Mechatronics Engineering

Labs

Electrical Drives and Actuators Laboratory

Electrical drives and Actuators laboratory (Lab Code: MR3361) is intended for students of Mechatronics Engineering branch for conducting various experiments in speed of electrical machines and actuators. Electrical drives and Actuators lab are equipped with over 12 experimental setups with several machines which include DC Machines, three phase induction motors, and single phase induction motor etc. Most experimental setup use power controller to control their speed. The lab facilities are enough to perform to experiments as per the syllabus. The drives and actuators lab is equipped with all kind of AC and DC machines required for undergraduate lab session and research activities in the field.

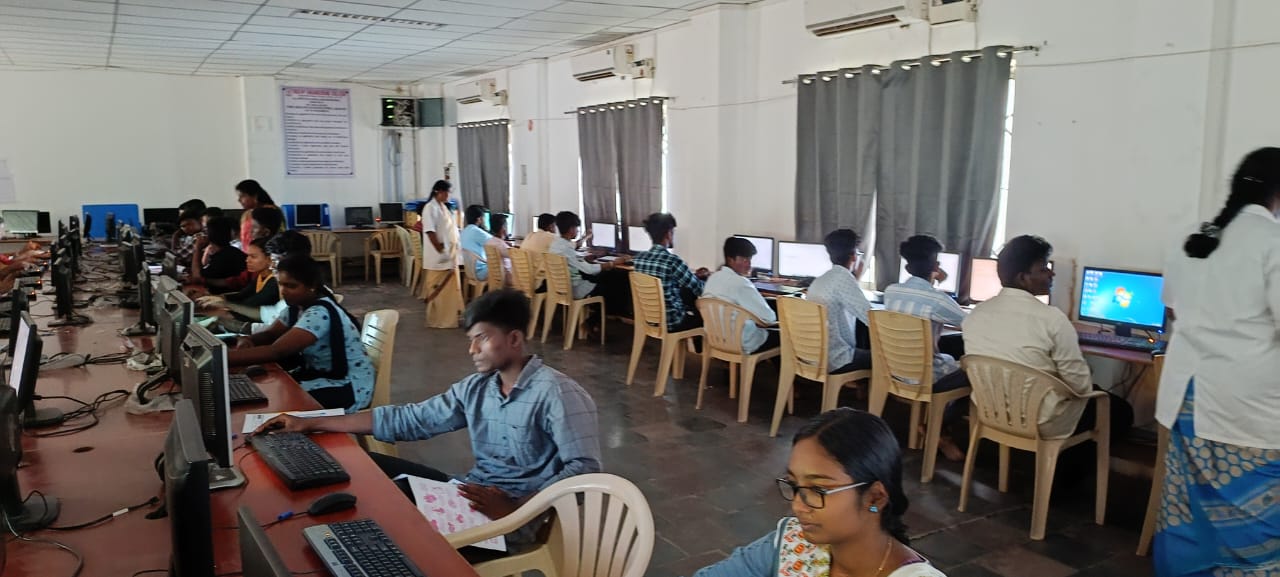

Design and Modelling Laboratory

Design And Modelling Laboratory is the most powerful tool in design and manufacturing industries with its reliability, flexibility, efficient and cost effectiveness. With CAD one can easily visualize and see the final product at the design stage itself with the aid of computer. Design and Modelling is a setup by Mechatronics Engineering department for enhancing the technical of students to design, visualize, and simulate their ideas before they are ever built or create using CAD tools. This lab is equipped with the latest CAD Modelling software and 30 No’s of computers with high configuration.

Embedded System and Programming Laboratory

Embedded systems are used everywhere - starting from simple everyday appliances to complex multimedia and biomedical equipments. The complexity of such systems is increasing at an exponential rate due to both advances in technology and demand for realization of ever more complex applications in the areas of communication, multimedia, networking and entertainment. System designers and software developers need to ensure that the final product meets a wide variety of design constraints including cost, power, energy, performance, safety, security, reliability, and so on.

Control System Engineering Laboratory

The Control System Engineering Laboratory at Mechatronics Engineering department is committed to broadly applicable research in the area of system identification and advanced process control. The goal of the research program is to develop fundamentally-oriented identication and control methodologies that improve human health and the efficiency, profitability, safety and environmental compliance of process system.

Sensors and Instrumentation Laboratory

Sensors and Instrumentation lab gives students in Mechatronics Engineering a hands-on introduction to the fundamental technology and practical applications of sensors. Capacitive, inductive, optical, ultrasonic and other sensing methods are examined. Instrumentation techniques incorporating computer control, sampling, data collection and analysis are reviewed in the context of real-world scenarios.

Industrial Automation Laboratory

The Industrial Automation Laboratory mainly consists of two laboratories. The basic automation laboratory provides students computer-based training and experimentation on basic automation technologies such as sensor technology, electrical actuation, pneumatics and hydraulics, control technology, PLC and industrial communication systems. The advanced automation laboratory consist of a state of the art hybrid (mixed) industrial bottling plant, where the student will be able to gain an exposure and hands on experience in commissioning, operating, maintaining and troubleshooting a real world industrial plant.

Manufacturing Technology Laboratory

Manufacturing Technology Laboratory is well equipped lab which provides idea on the practical knowledge of several steps of casting, pattern usage, mould creation, gating design. Produce a casing and check casting defects. This laboratory is scheduled for 4th semester mechatronics engineering students. Apart from curriculum some additional experimental setups are there which helps the students to enhance their knowledge. Students also get opportunity to implement their ideas through various application oriented micro projects.

Kinematics and Dynamics of Machinery Laboratory

Kinematics and Dynamics of Machinery lab provides the practical knowledge about various mechanisms and their applications. Students will go through the various experiments of different mechanisms like cam-follower mechanism, gears, gear train, etc., There are 13 experiments in this lab. Students have to perform all experiments from the list.

Mechatronics System Design Laboratory

Mechatronic system design strives to integrate mechanical, electronic, optical and computer technologies in order to create “optimal” products and processes. Basic concepts and fundamental principles will be reviewed in this course. Students will develop the knowledge and skills necessary to adopt an interdisciplinary approach to mechatronic system design through the lectures, hands-on laboratory assignments, and term project. Specific topics and learning objectives include: a. Identify and explain the components and characteristics of a mechatronic system. b. Explain how intelligent products and systems are developed. c. Expand engineering design knowledge to encompass mechatronic design principles. d. Explain the role of sensors, actuators, control, and machine intelligence in product performance. e. Apply product design and systems engineering concepts to the development of a mechatronic system. f. Adapt mechanical designs into mechatronic designs.

Robotics and Machine Vision Laboratory

Robotics and machine Vision laboratory researches and develops technologies that allow computerized systems to perceive and interpret the world, make decisions, and act. We believe that that robotics, as well as artificial perception and intelligence, will play an increasingly important role in the future of humanity- in daily lives, in industry and economy, in politics. The goal of robotics and machine vision is become a major player in shaping this future.

Computer Aided Design and Manufacturing Laboratory

The Computer-Aided Design/Computer-Aided Manufacturing Laboratory is maintained in the Department of Industrial Engineering. The lab allows students and faculty to work with the latest computer-aided design and numerical control equipment including a computer-controlled turning and milling centers, CAD work stations equipped with the latest CAD/CAM/FEM/Visualization software and computer vision systems.

Robotics Laboratory

In the lab, students will program various robot tasks that challenge the robot’s ability to meet its specifications. Experiments are designed to highlight robot accuracy, repeatability, programmability, and manoeuvrability, off-line Vs on-line programming, force and impedance control. Our educational objective is to focus on the methods used for difficult assembly tasks requiring some level of manipulative “skill” and force feedback, not on the “conventional” robot assembly task. The assembly task is used to examine issues associated with programming robots, such as taking advantage of compliance, sensing and fixture design. During the experiments, measurements are made to highlight the robot’s static and dynamic accuracy and repeatability achieved when programming the robot end effector’s position, velocity, and path, and the forces generated under a variety of conditions.